Darshana Industries combines the power of a global manufacturer with the character of a local business.

With a focus on our core values of integrity, high ethics, and quality, Darshana Industries has expanded over the years thanks to the discipline and drive of our employees. What started as a simple manufacturing operation for control panel components has grown into a versatile and innovative organization that can meet any access hardware need.

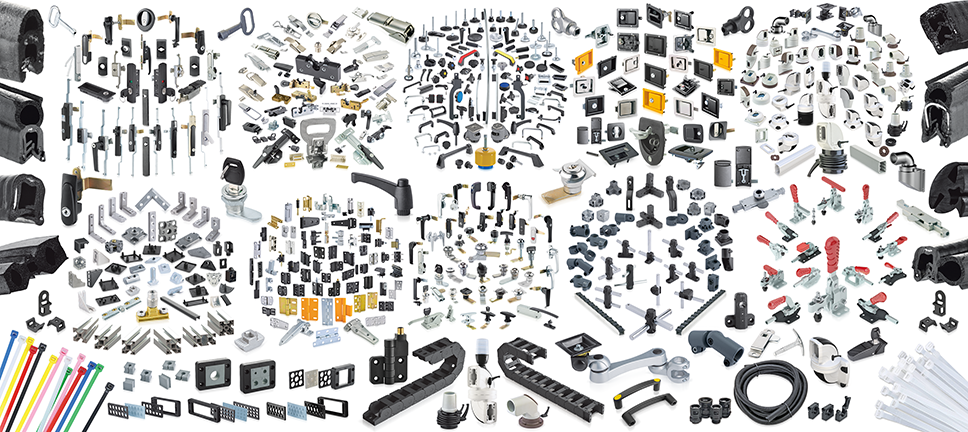

Over the years we have expanded our product offering to cover, machine tool handles, console accessories, support arm systems, conveyor components, electronic access control units, vehicle locks, and more as we adapt to the ever-changing needs of industries worldwide.

Each product is engineered to meet the highest standards of durability and performance, ensuring seamless integration across various industrial applications.

With a dedicated workforce of over 300 employees, we operate with 100% in-house manufacturing capabilities, utilizing advanced processes such as injection molding, die casting, stamping, laser cutting, powder coating, and foaming. Our robust R&D and tooling setup empowers us to continuously innovate and maintain our leadership position in the industry.

Darshana Industries has an extensive distribution network with 22 distributors covering 80% of India, ensuring our products are readily accessible to customers nationwide. Additionally, our widespread dealer network extends across global markets, reinforcing our commitment to delivering excellence on an international scale.

At Darshana Industries, we are driven by a commitment to quality, precision, and customer satisfaction. Our relentless pursuit of excellence has fueled our continuous growth, making us a trusted partner for industries worldwide.

About Darshana Industries - Leaders in Industrial Components & Engineering Solutions

We have proved ourselves as a flexible and versatile manufacturer, offering a huge range of design options, with the help of in-house facilities such as Plastic Molding, Zinc Alloy Pressure Die Casting, Rubber Molding, Conveyorised Powder Coating & Metal Punching.

Our Capabilities

Now spread over an area of 175,000 sq. ft. with over 290 employees, Darshana Industries has grown into a flexible innovator and versatile manufacturer, offering a huge range of design options, with the help of in-house facilities.

Research and Development

Our dedicated R&D team, with over two decades of experience, specializes in designing and developing cutting-edge solutions in machine and panel accessories. Backed by state-of-the-art software and in-house tooling capabilities, we offer rapid prototype support to accelerate innovation.

Plastic Molding

We operate over 15 machines, including horizontal injection molding, vertical molding, and vacuum molding for rubber. With machine capacities ranging from 45 to 180 tons, we ensure the production of high-quality plastic and rubber parts.

Zinc Die Casting

Equipped with more than 10 state-of-the-art machines ranging from 80 to 150 tons, we produce high-precision pressure diecast (PDC) components that meet stringent quality standards.

Powder Coating

Our advanced powder coating facility includes a 7-tank cleaning process and a conveyorized automated powder coating booth. With dedicated powder storage for different colors, we achieve a 100% consistent finish across all shades.

Stamping Unit

Featuring cutting-edge press machines, laser machines, and press brakes, our stamping unit allows us to manufacture a wide range of metal components with precision and efficiency.

Foaming

Our in-house foaming capabilities enable the production of high-quality foam-based components for enhanced durability and performance in industrial applications.

Automatic Assembly Units

We leverage automated assembly units to enhance production efficiency and ensure consistency in the assembly of intricate machine and panel accessories.

Machining Centers

Our advanced machining centers are equipped with precision tools for shaping and finishing components with high accuracy, meeting the most demanding industrial specifications.

Turning Centers

We utilize high-performance turning centers to manufacture rotational components with precise tolerances, optimizing performance, and reliability.

Drilling and Tapping

Our dedicated drilling and tapping stations ensure the production of high-quality threaded components, facilitating seamless assembly and functionality.

Key Manufacturing

Using high-quality machines, we produce various types of security keys and barrels. Our capabilities ensure the creation of highly secure products with multiple key combinations.